Advantages of Tantalum Nickel Surface Alloy

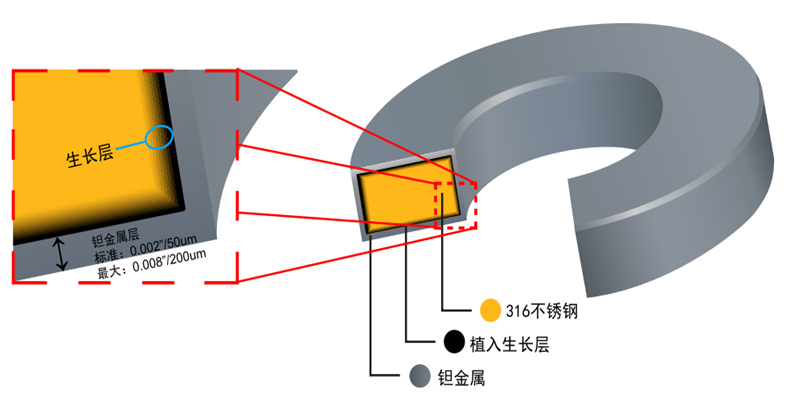

The proprietary gas-phase tantalum evaporation surface alloy technology used by Ains can form an extremely sturdy, uniform, inert, and corrosion-resistant pure tantalum surface layer on ready-made stainless steel valves and related equipment. Tantalum atoms will actually grow into nickel based materials to form a transition layer, thus forming an inseparable nano pure tantalum surface layer. This layer conforms to complex geometric shapes, such as the valve body and orifice, ensuring surface uniformity. Vapor phase tantalum evaporation surface alloy technology treatment provides excellent corrosion resistance and pitting resistance, which can extend the service life of chlorinated compounds, hot acids, and other corrosive chemicals. The sturdy pure tantalum surface layer can withstand high pressure and corrosive conditions in pipelines, containers, and process equipment. These characteristics are attributed to special alloys such as Hastelloy ®*、 Inconel ®**、 Valves made of zirconium and titanium provide an economical alternative with shorter delivery times.

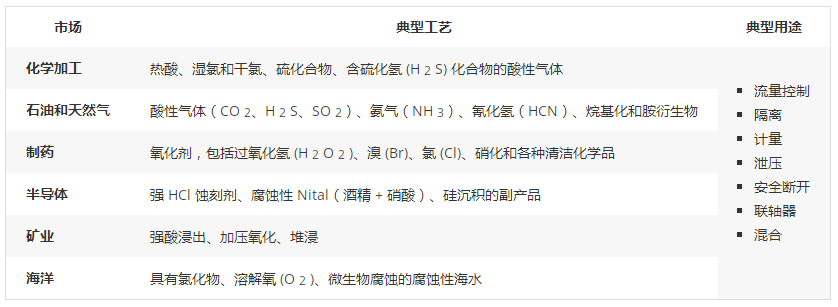

Field Of Use

Key Technology

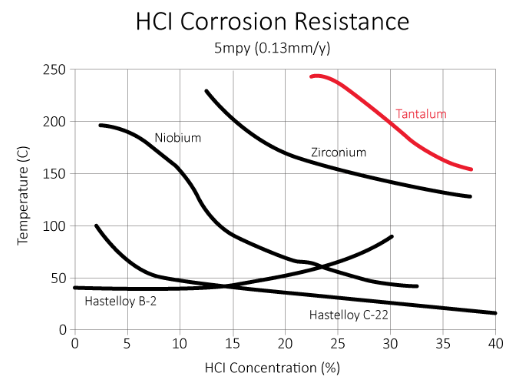

Hastelloy ®* Inconel ®**、 Zirconium, titanium, and stainless steel valve components are susceptible to stress corrosion cracking (SCC) and pitting corrosion, especially in hot acids such as HCl. Processing has the following beneficial characteristics:

l Chemical resistance to SCC and pitting in many corrosive media and environments.

l Under acidic conditions at high temperatures (>200 ° C), including concentrated hydrochloric acid (HCl) and sulfuric acid (H 2 SO 4), the tantalum layer remains passivated and inert corroded.

l Excellent corrosion resistance to damp, dry chlorine gas and other chlorinated environments.